Pharmaceutical Technology

Description

The ambition of the research group in Pharmaceutical Technology is to conduct methodological and basic mechanistic research that can contribute to the development of better and more cost effective pharmaceuticals. We will develop firstly, new and improved drug delivery solutions and secondly, formulation tools for a more effective development and manufacturing of drug products. The core expertise of the group is powder science and technology which is a scientific discipline with applications to different type of products, including pharmaceuticals. An important and common research question for the research projects of the group is how critical properties of particles and particle systems can be assessed, controlled and predicted. The main applications of the research are formulation of medicines for peroral and pulmonary administration. Three research projects are currently developed within the group, i.e.: (1) Analytical powder compression; (2) Formulation of dry granulated powders; (3) Formulation of inhalation powders. The research is part of the research program of the Swedish Drug Delivery Center (SweDeliver).

Learn more about our research areas

Analytical powder compression

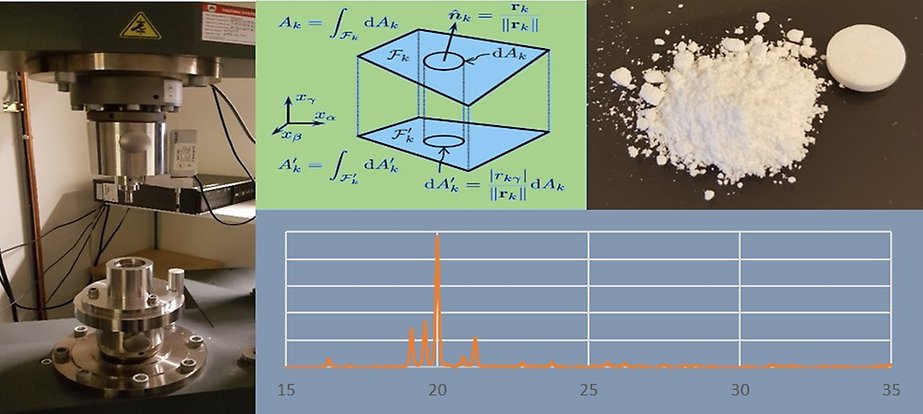

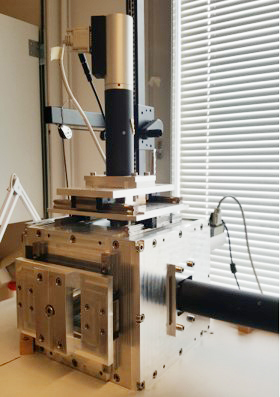

Tablets are typically fabricated by confined powder compression using tablet tooling of different types. Due to the application of force by the tableting punches, the volume of the powder held in the die is reduced until at coherent tablet of required fracture strength, attrition resistance and porosity is formed. Mechanical strength is hence a fundamental quality attribute of tablets and the ability of the powder to cohere into a tablet must be controlled. The powder compression event involves a series of physical phenomena on the particle level which are expressed during a short period of time. Particles constituting the powder are typically of varying size, shape and porosity and are hence difficult to reproducibly characterize as single particles. An alternative is to derive particle properties from powder compression data and the term analytical powder compression has been coined for such an approach. Analytical powder compression (APC) is defined as the determination of compression parameters as firstly, indications of the mechanical and friction properties of particles and secondly, as predictors of the ability of the powder to form tablets. The research group has developed a protocol for APC and is now further developing this protocol in terms of the assessment of elastic particle properties and the prediction of powder tabletability and compactibility.

Formulation of dry granulated powders

Poorly soluble drugs, such a BCS class II drugs, are typically used in drug products as micronized particles. In order to enable tablet manufacturing of such fine particulate material, the particles are often pre-processed by a size enlargement process during which a granular powder is prepared which consists of granules considerably larger than the starting material. An emerging granulation technology for large scale tablet manufacturing is dry granulation by roll compaction, a technology suitable for continuous manufacturing. The research group studies how physical and technical properties of the granules are affected by variations in powder composition and process parameters. The aim is to derive a mechanistic understanding of the compression properties of the granules enabling a rational approach to their formulation. The approach used in these studies is the sequential relationship composition – microstructure – single granule mechanics - tableting performance. Both traditional granules and model granules of uniform size and shape are used in research.

Formulation of inhalation powders

Different types of dosage forms are used to deliver drugs to the lung och among these, inhalations powders are common due to their patient friendly properties. In order for particles to be inhalable and be deposited in the lung, they have to be very fine with an aerodynamic particle diameter typically below 5 mm. To enable automated machine filling of the inhaler as well as emptying of the inhaler and subsequent particle aerosolization during use, the micronized particles usually have to be agglomerated. Examples of two different types of agglomerates used in drug products, which hence represents important formulation technologies for inhalation powders, are adhesive mixtures (structured agglomerates) and soft non-structured agglomerates. In the research group, physical and formulation properties of agglomerates for inhalation are studied, primarily adhesive mixtures. A classification system, denoted a blend state theory, of adhesive mixtures has been introduced and the impact of blend state on powder physico-technical and aerosolisation properties has been demonstrated for different carriers and drugs. With this conceptual description as starting position work is on-going how the blend state can be controlled as well as the possibility to affect the interparticulate forces acting in the blend.

Publications

Part of Pharmaceutical development and technology (Print), p. 509-519, 2023

- DOI for Tabletability and compactibility of alpha-lactose monohydrate powders of different particle size. II: predicted relationships

- Download full text (pdf) of Tabletability and compactibility of alpha-lactose monohydrate powders of different particle size. II: predicted relationships

Part of Pharmaceutical development and technology (Print), p. 319-330, 2022

- DOI for Tabletability and compactibility of alpha-lactose monohydrate powders of different particle size. I. Experimental comparison

- Download full text (pdf) of Tabletability and compactibility of alpha-lactose monohydrate powders of different particle size. I. Experimental comparison

Effect of fluid velocity and particle size on the hydrodynamic diffusion layer thickness

Part of European journal of pharmaceutics and biopharmaceutics, p. 1-10, 2022

- DOI for Effect of fluid velocity and particle size on the hydrodynamic diffusion layer thickness

- Download full text (pdf) of Effect of fluid velocity and particle size on the hydrodynamic diffusion layer thickness

Part of International Journal of Pharmaceutics, 2022

- DOI for Effect of pressure drop on the in vitro dispersion of adhesive mixtures of different blend states for inhalation

- Download full text (pdf) of Effect of pressure drop on the in vitro dispersion of adhesive mixtures of different blend states for inhalation

Part of Obesity, p. 2222-2232, 2022

- DOI for Effects of a novel weight-loss combination product containing orlistat and acarbose on obesity: A randomized, placebo-controlled trial

- Download full text (pdf) of Effects of a novel weight-loss combination product containing orlistat and acarbose on obesity: A randomized, placebo-controlled trial

Part of Powder Technology, 2022

- DOI for Effect of excipient properties and blend ratio on the compression properties of dry granulated particles prepared from microcrystalline cellulose and lactose

- Download full text (pdf) of Effect of excipient properties and blend ratio on the compression properties of dry granulated particles prepared from microcrystalline cellulose and lactose

Part of Powder Technology, 2022

- DOI for Deciphering the role of granule deformation and fragmentation for the tableting performance of some dry granulated powders

- Download full text (pdf) of Deciphering the role of granule deformation and fragmentation for the tableting performance of some dry granulated powders

Part of International Journal of Pharmaceutics, 2021

- DOI for On the relationship between blend state and dispersibility of adhesive mixtures containing active pharmaceutical ingredients

- Download full text (pdf) of On the relationship between blend state and dispersibility of adhesive mixtures containing active pharmaceutical ingredients

Part of Pharmaceutics, 2021

- DOI for Determination of Intrinsic Drug Dissolution and Solute Effective Transport Rate during Laminar Fluid Flow at Different Velocities

- Download full text (pdf) of Determination of Intrinsic Drug Dissolution and Solute Effective Transport Rate during Laminar Fluid Flow at Different Velocities

Safety of a Novel Weight Loss Combination Product Containing Orlistat and Acarbose.

Part of Clinical Pharmacology in Drug Development, p. 1242-1247, 2021

- DOI for Safety of a Novel Weight Loss Combination Product Containing Orlistat and Acarbose.

- Download full text (pdf) of Safety of a Novel Weight Loss Combination Product Containing Orlistat and Acarbose.

Part of Obesity Science & Practice, p. 313-323, 2020

- DOI for Effects of a novel combination of orlistat and acarbose on tolerability, appetite, and glucose metabolism in persons with obesity

- Download full text (pdf) of Effects of a novel combination of orlistat and acarbose on tolerability, appetite, and glucose metabolism in persons with obesity

Part of International Journal of Pharmaceutics, p. 130-137, 2019

Part of Powder Technology, p. 74-81, 2019

Part of International Journal of Pharmaceutics, p. 148-160, 2019

- DOI for Linking carrier morphology to the powder mechanics of adhesive mixtures for dry powder inhalers via a blend-state model

- Download full text (pdf) of Linking carrier morphology to the powder mechanics of adhesive mixtures for dry powder inhalers via a blend-state model

Part of International Journal of Pharmaceutics, 2019

- DOI for Atypical compaction behaviour of disordered lactose explained by a shift in type of compact fracture pattern

- Download full text (pdf) of Atypical compaction behaviour of disordered lactose explained by a shift in type of compact fracture pattern

Milling induced amorphisation and recrystallization of alpha-lactose monohydrate

Part of International Journal of Pharmaceutics, p. 140-147, 2018

Part of European journal of pharmaceutics and biopharmaceutics, p. 28-37, 2018

- DOI for A hybrid approach to predict the relationship between tablet tensile strength and compaction pressure using analytical powder compression

- Download full text (pdf) of A hybrid approach to predict the relationship between tablet tensile strength and compaction pressure using analytical powder compression

Effect of milling on the plastic and the elastic stiffness of lactose particles

Part of European Journal of Pharmaceutical Sciences, p. 138-145, 2018

- DOI for Effect of milling on the plastic and the elastic stiffness of lactose particles

- Download full text (pdf) of Effect of milling on the plastic and the elastic stiffness of lactose particles

Part of Journal of Pharmaceutical Sciences, p. 1920-1927, 2018

Determination of interfacial amorphicity in functional powders

Part of Abstracts of Papers of the American Chemical Society, 2018

Part of International Journal of Pharmaceutics, p. 143-156, 2018

Part of International Journal of Pharmaceutics, p. 120-131, 2018

Determination of Interfacial Amorphicity in Functional Powders

Part of Langmuir, p. 920-926, 2017

Part of International Journal of Pharmaceutics, p. 215-227, 2017

- DOI for Comminution-amorphisation relationships during ball milling of lactose at different milling conditions

- Download full text (pdf) of Comminution-amorphisation relationships during ball milling of lactose at different milling conditions

Powder compression mechanics of spray-dried lactose nanocomposites

Part of International Journal of Pharmaceutics, p. 1-10, 2017

Part of International Journal of Pharmaceutics, p. 488-504, 2016

- DOI for Considerations on the quantitative analysis of apparent amorphicity of milled lactose by Raman spectroscopy

- Download full text (pdf) of Considerations on the quantitative analysis of apparent amorphicity of milled lactose by Raman spectroscopy

Part of Chemical engineering research & design, p. 183-191, 2016

Inhibition of Recrystallization of Amorphous Lactose in Nanocomposites Formed by Spray-Drying

Part of Journal of Pharmaceutical Sciences, p. 3760-3769, 2015

An apparatus for confined triaxial testing of single particles

Part of Powder Technology, p. 121-127, 2015

- DOI for An apparatus for confined triaxial testing of single particles

- Download full text (pdf) of An apparatus for confined triaxial testing of single particles

Part of Journal of Pharmaceutical Sciences, p. 2029-2039, 2015

Part of International Journal of Pharmaceutics, p. 326-333, 2014

Part of International Journal of Pharmaceutics, p. 3-12, 2013

- DOI for The degree of compression of spherical granular solids controls the evolution of microstructure and bond probability during compaction

- Download full text (pdf) of The degree of compression of spherical granular solids controls the evolution of microstructure and bond probability during compaction

Mechanism of Amorphisation of Micro-Particles of Griseofulvin During Powder Flow in a Mixer

Part of Journal of Pharmaceutical Sciences, p. 4036-4045, 2013

Part of International Journal of Pharmaceutics, p. 295-299, 2013

- DOI for A comparison between two powder compaction parameters of plasticity: The effective medium A parameter and the Heckel 1/K parameter

- Download full text (pdf) of A comparison between two powder compaction parameters of plasticity: The effective medium A parameter and the Heckel 1/K parameter

Part of Pharmaceutical development and technology (Print), p. 333-343, 2012

An experimental evaluation of an effective medium based compaction equation

Part of European Journal of Pharmaceutical Sciences, p. 49-55, 2012

- DOI for An experimental evaluation of an effective medium based compaction equation

- Download full text (pdf) of An experimental evaluation of an effective medium based compaction equation

A protocol for the classification of powder compression characteristics

Part of European journal of pharmaceutics and biopharmaceutics, p. 209-216, 2012

Part of Colloids and Surfaces B, p. 53-60, 2012

Part of European Journal of Pharmaceutical Sciences, p. 199-209, 2011

- DOI for Flowability of surface modified pharmaceutical granules: A comparative experimental and numerical study

- Download full text (pdf) of Flowability of surface modified pharmaceutical granules: A comparative experimental and numerical study

Degree of compression as a potential process control tool of tablet tensile strength

Part of Pharmaceutical development and technology (Print), p. 599-608, 2011

Part of Journal of Pharmacy and Pharmacology (JPP), p. 1265-1273, 2011

Effect of spherical-agglomerate strength on the distribution of force during uniaxial compression

Part of Powder Technology, p. 283-290, 2011

- DOI for Effect of spherical-agglomerate strength on the distribution of force during uniaxial compression

- Download full text (pdf) of Effect of spherical-agglomerate strength on the distribution of force during uniaxial compression

Part of European journal of pharmaceutics and biopharmaceutics, p. 425-435, 2010

Effect of lubrication on the distribution of force between spherical agglomerates during compression

Part of Powder Technology, p. 69-74, 2010

- DOI for Effect of lubrication on the distribution of force between spherical agglomerates during compression

- Download full text (pdf) of Effect of lubrication on the distribution of force between spherical agglomerates during compression

Part of Pharmaceutical development and technology (Print), p. 233-239, 2009

Part of European journal of pharmaceutics and biopharmaceutics, p. 395-401, 2009

Clinical study shows improved absorption of desmopressin with novel formulation

Part of Pharmaceutical research, p. 1618-1625, 2009

Effective Kawakita parameters for binary mixtures

Part of Powder Technology, p. 270-275, 2009

A particle rearrangement index based on the Kawakita powder compression equation

Part of Journal of Pharmaceutical Sciences, p. 1053-1063, 2009

An effective-medium analysis of confined compression of granular materials

Part of Powder Technology, p. 228-232, 2009