SEK 22 million for Uppsala research on smart patches

Text

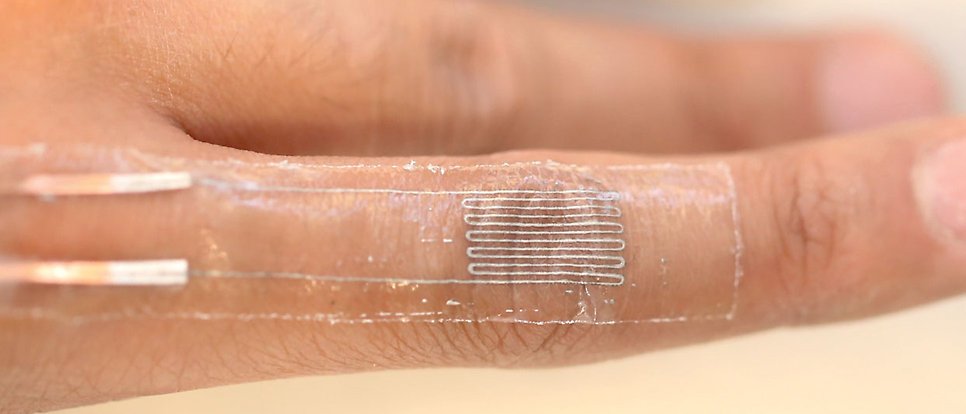

Within the EU project PERSIMMON, stretchable electronic patches will be further developed to make them biodegradable, among other advantages. Photo: SINTEC

Hello Klas Hjort, Professor of Materials Science and Head of the Microsystems Technology programme at the Department of Materials Science and Engineering. You coordinate the EU project known as PERSIMMON, which was recently awarded just over SEK 90 million, of which about SEK 22 million goes to Uppsala University. What is the project about?

“PERSIMMON stands for ‘Personalized Sustainable Smart Patch Omnificence’. In layman’s terms, it’s a customized and sustainable ‘smart patch’. There’s a huge need for this type of sensor patch for personal health monitoring, especially for chronically ill patients who need to use them in their everyday lives. The patches contain tiny modules made of common electronic components and wirelessly transmit information to a smartphone. This makes it possible to safely monitor blood pressure and body temperature in patients with cardiovascular disease, or glucose levels in diabetics, for example. Smart patches are also of interest to everyone from regular exercisers to elite athletes in sports such as skiing and swimming who want to measure and analyse important bodily functions.

The problem is that these patches are disposable products, and when they’re thrown away they generate a lot of microplastics that are harmful to the environment. We want to make the patches biodegradable, while also making it easier to recover the electronic components and metals if they are collected after use. That’s what this project is all about.”

What does it take to make the patches sustainable, and what happens to the electronic components that cannot be broken down?

“We use polymers made from biomaterials, which can be composted or broken down in a harmless hot water solution, so that no microplastics are formed and we can recover the electronic components and the metal. What breaks down is the capsule around the electronic circuits. Then we will recycle the metal in the patch’s printed circuit. That will also make it easy to clean the electronic components, which can then be recycled or even reused.”

Klas Hjort, Professor of Materials Science, Uppsala University.

You have previously researched smart patches as part of the SINTEC project – how does PERSIMMON differ from that endeavour?

“Most of the software and applications are transplants from the old EU project, but we’re adding a new sensor component, among other things. It’s a novel chemical sensor created by Professor Hugo Nguyen, which we’re continuing to develop. The sensor allows chemical analysis to be conducted directly against the skin and is more sensitive and stable than many other chemical sensors. We’ve found a way to make the sensors incredibly tiny, smaller than a cubic micrometer. This means that even if they are heated to high temperatures, they don’t burn the skin.

Other innovations that will be introduced in PERSIMMON are based on AI and digital SMT. We also have a new type of promising sensor material under development by a research team in Linz. In total, the project has 13 partners in Sweden and Europe, and several of us have worked together for many years.”

What will the government appropriations be used for at Uppsala University?

“We need to hire new staff and take advantage of people who are already at the university. For the purposes of this project, the following persons and activities will be involved: Klas Palm, who researches the circular economy, Robin Augustine and his microwave technology for medical applications, and Thiemo Voigt, who’s a wizard with wireless networks. Uppsala University has a number of areas of expertise which, when combined, make us uniquely equipped to solve a problem. That’s what's so great about a full-scale university!”

Anneli Björkman

FACTS PERSIMMON (Personalized Sustainable Smart Patch Omnificence)

The four-year Horizon Europe RIA PERSIMMON project has a budget of just over SEK 90 million, of which approximately SEK 22 million has been allocated to Uppsala University. The project is expected to be launched in September 2024 and brings together 11 partners from the Netherlands, Italy, Slovenia, Spain, Sweden and Austria. In addition to Uppsala University, Sweden’s contributors include the companies Mycronic and Beneli. PERSIMMON is coordinated by Professor Klas Hjort of the Department of Materials Science and Engineering and involves three teams based at Uppsala University’s Ångström Laboratory.

Learn more:

SINTEC | Soft Intellingent Epidermal Communication Platform | H2020 (sintec-project.eu)

Smart patches help us keep track

Robotic textiles for everything from breathing recovery to feeling surfaces in Space

Uppsala researchers develop flatworm robots in EU project

Division of Microsystems Technology (MST) at the Department of Materials Science and Engineering